Posts Tagged ‘Additive Manufacturing’

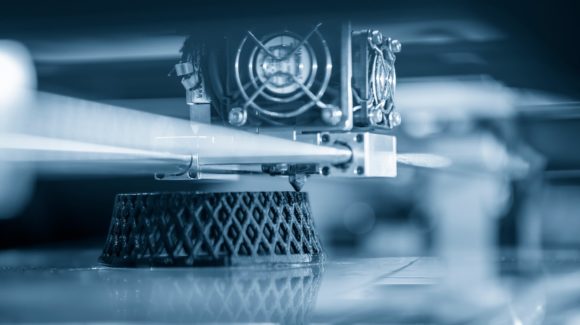

General Atomics Aeronautical Systems, Inc. (GA-ASI) has established a new Center of Excellence for its Additive Design and Manufacturing (AD&M). The Center is focused on rapid-reaction manufacturing of GA-ASI’s line of UAS using fully functional and flight-ready Additive Manufacturing (AM) applications, research and development, large-scale tooling, and next-generation flight hardware. Over the ...

General Atomics Aeronautical Systems, Inc. (GA-ASI) has partnered with Australia-based Conflux Technology on the development of a heat exchanger. The part is being developed using a metal Additive Manufacturing process for possible integration onto GA-ASI’s line of Remotely Piloted Aircraft Systems (RPAS). Conflux Technology is an Additive Manufacturing applications company based in ...

Travis air base in California has produced the first certified 3D printed aircraft parts with the 60th Maintenance Squadron. The Air Force used the industrial-sized Stratasys F900 printer to produced the certified 3D printed aircraft parts with the 60th Maintenance Squadron. The Travis Air Base in California used the Stratasys to ...

Researcher groups from the US military are advancing 3D Printing for use in Naval shipyards in Keyport, Washington. Naval Sea Systems Command (NAVSEA) Tactical Innovation Implementation Lab (TIIL) is advancing and maturing additive manufacturing (AM, also known as 3D printing) technology into the naval shipyards to support the fleet through Print ...

Next