Following a design brief from Dstl, Frazer-Nash, the UK leading systems and engineering technology company, has presented a number of Collective Protection (COLPRO) systems for the armed forces.

COLPRO systems create a protective environment against chemical, biological and radiological threats, allowing military personnel to move freely within a toxic free area, without having to wear individual protective equipment. COLPRO systems include decontamination areas, breathable air quality, and function as a stand-alone structure.

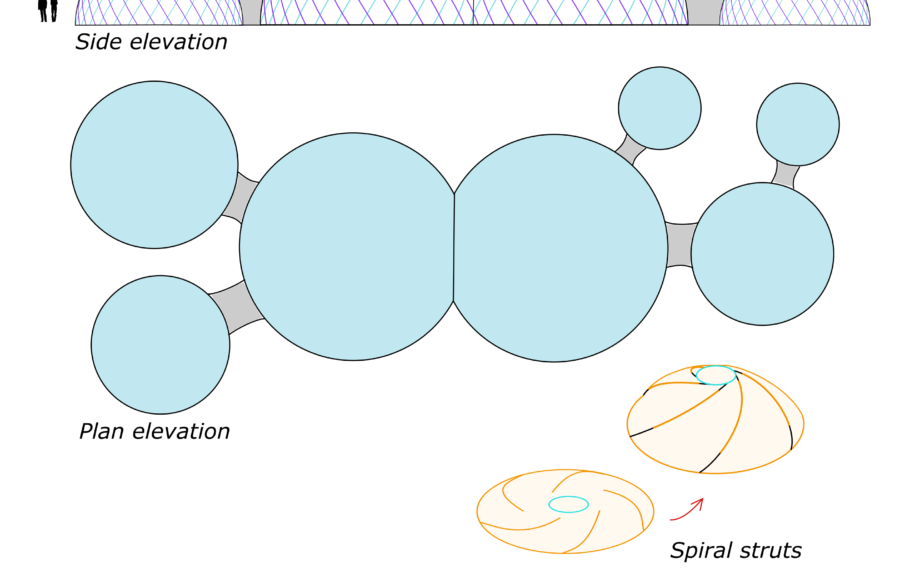

Dstl wanted to identify and develop novel concept designs for transportable COLPRO systems over three sizes: small (to house 20 personnel), medium (to house 50 personnel) and large (to house 250 personnel).

The company undertook an in-depth review of transportable structures, assessing the requirements for COLPRO and evaluating the design options.

Key requirements of the design looked to negate some of the issues current systems have, including erection time, size and weight of the units, restricted space and a lack of modularity.

Frazer-Nash consulted with Dstl throughout the design process, which culminated in the development of several concepts in a variety of sizes. CAD models were created for each size and scaled prototypes built for further demonstration

The preferred large and medium designs offered a modular form, with a large area capable of housing vehicles, but only required a small number of personnel to erect and strike the systems. The chosen small-sized concept offered a self-supporting structure with relatively few parts, rigid panels which are more durable and easier to seal, and rapid strike and erect.

Further work is now planned to develop the designs, prototype at scale and test in the field, to ensure they meet the needs of the military personnel who will be using them.

If you would like to join our community and read more articles like this then please click here