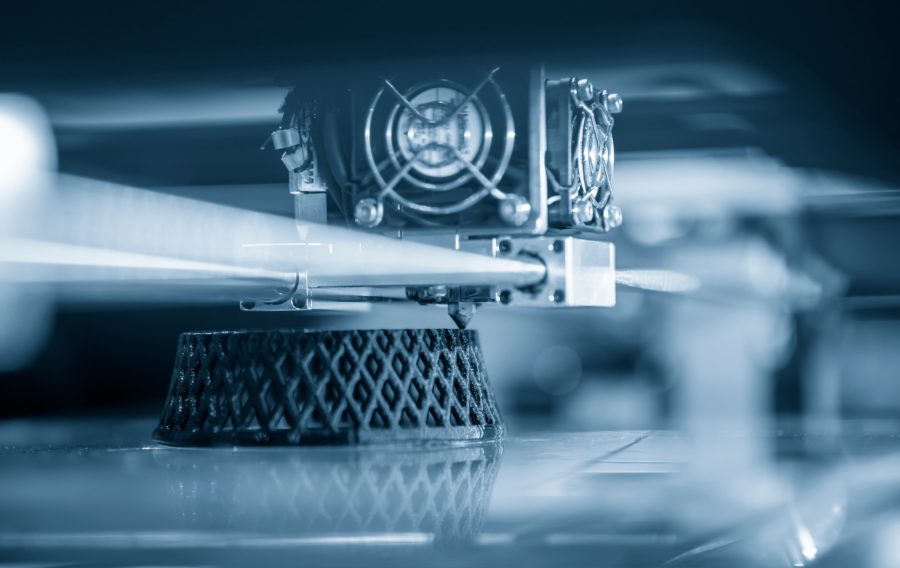

Travis air base in California has produced the first certified 3D printed aircraft parts with the 60th Maintenance Squadron.

The Air Force used the industrial-sized Stratasys F900 printer to produced the certified 3D printed aircraft parts with the 60th Maintenance Squadron. The Travis Air Base in California used the Stratasys to produce replacement latrine covers for the C-5M Super Galaxy.

The printer was made operational through an eight-month process and blueprints for designs are approved by the University of Dayton Research Institute. The printer allows the air force to save money on parts and cut down on long manufacturing and delivery periods.

Master Sgt. John Higgs, 60th Maintenance Squadron Aircraft Metals Technology Section Chief, said: “It brings us a capability that we’ve never had before. There’s so many possibilities available to us right now. We’re just scratching the surface.”

“The Joint Engineering Data Management Information Control System is where we go to download already approved blueprints. Now, the University of Dayton Research Institute is working with the engineers to get those parts they developed into JEDMICS.”

“The latrine covers we just printed usually take about a year from the time they’ve been ordered to the time they’ve been delivered. We printed two of the covers in 73 hours. There were facility requirements that had to be met, and then installation and certification processes to complete, After, we needed to decide who could operate the printer, then have a UDRI instructor certify them.”

Currently, the Travis Air Base has the only operational printer and is taking requests from other bases for parts. The Air force hopes to use the printer for more than just aircraft parts, printing for other organisations within the military, and across all defence organisations and sectors.

If you would like to join our community and read more articles like this then please click here.

3D Printing Additive Manufacturing aircraft Delivery industry US Air Force US military