Elbit Systems and SWISSto12 have announced a long-term cooperation agreement for the development and production of 3D-printed RF antennas and subsystems for Elbit Systems’ Naval EW programs in several countries.

The successful industrialisation of SWISSto12’s unique 3D printing technology for serial production in the aerospace and defence industries assures high-performance and cost effective solutions.

Jakob Baumann, Chairman of the Board of Elbit Switzerland, said: “We feel very fortunate to partner with SWISSto12. Their innovative and forward-thinking approach is a perfect fit for Elbit Systems. We are convinced that we will be able to implement many successful projects together. It’s a perfect example how offset was used to bring two companies together.”

Elbit Systems was selected by numerous countries to provide advanced EW solution, in different domains of operation, including the US, Canada, Germany, Portugal, Israel and other.

“Elbit’s well known ambition to find new innovative solutions is a perfect fit with SWISSto12’s unique technology and product portfolio – we are truly honoured to become Elbit’s strategic partner for RF systems made by 3D printing” said Dr. Emile de Rijk, founder and CEO of SWISSto12. “This strategic partnership allows us to scale our production and business volume to the next level and comes as an additional customer focused success story” he continued.

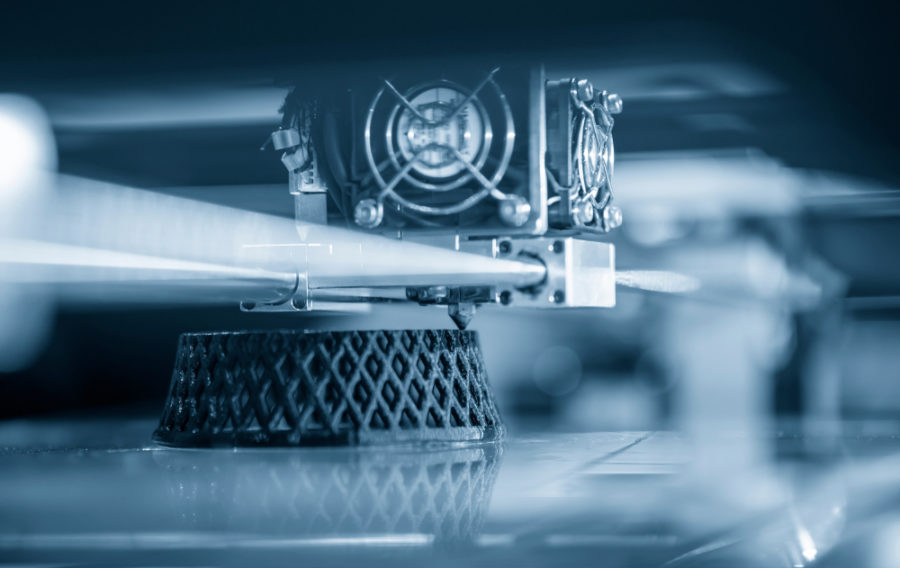

Additive Manufacturing (AM), or 3D printing, is an advanced manufacturing technology that has gained traction in the defense and aerospace industries over the last decade. AM allows for the manufacture of highly complicated, intricate and non-conventional designs that free products from typical manufacturing constraints that have long limited their performance, weight, size and cost competitiveness.

SWISSto12 pioneered the development of tailored and patented AM technologies aimed at delivering advanced RF performance, size, and weight savings as well as product competitiveness through optimized manufacturing tolerances, surface finishes, plating techniques, and RF designs.

The technology and associated products address the increasingly challenging size, weight, power, and cost (SWaP-C) requirements of Tier 1 and 2 customers.

If you would like to join our community and read more articles like this then please click here