BAE Systems has signed an MoU with Renishaw to improve the capability of additive manufacturing systems for defence and aerospace.

The Memorandum of Understanding (MoU) signed by BAE and Renishaw aims to create a more cost-effective, faster, and more capable additive manufacturing, or 3D printing, process. The MoU was signed at BAE’s manufacturing facilities in Samlesbury, Lancashire.

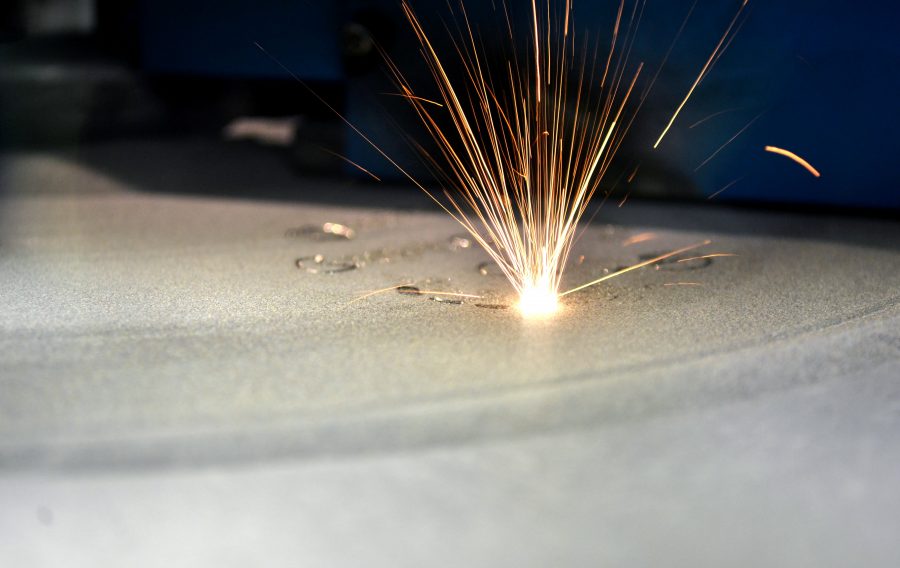

The site is already home to several Renishaw advanced AM machines which form part of a 1,000 square metre dedicated New Product Development & Process Development Centre (NPPDC), where the latest emerging technologies and processes such as AM and Virtual Reality are explored and tested for application into aircraft design and manufacture. With a particular focus on additive manufacturing, the agreement aims to exploit the latest technologies and processes to continually improve advanced manufacturing capabilities.

Andy Schofield, Manufacturing & Materials Strategy & Technology Director for BAE Systems, said: “Additive manufacturing has and will continue to deliver significant benefits to our sector. Renishaw is a world leader in additive manufacturing and we have been impressed with the quality of parts produced on its machines.”

“This agreement allows us to create a more open and collaborative environment to share ideas and knowledge. In an environment of fast developing technology and challenged budgets, collaboration and innovation are absolutely essential in order to retain cutting edge capability. I’m really excited by the potential this partnership has to help us deliver that.”

BAE has been researching 3D printing for over two decades and has used it in the production of Typhoon jets and new technology under the Tempest project. The contract is the latest in BAE projects across academia, industry, and business.

If you would like to join our community and read more articles like this then please click here.

3D Printing BAE Systems capability Defence industry MoU partnership Research